|

|

|

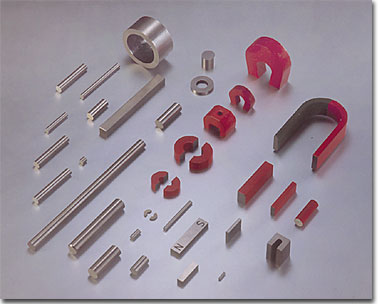

| AlNiCo magnets basically consist of aluminum, nickel, cobalt, copper, iron and titanium. Most AlNiCo magnets are manufactured using typical foundry casting techniques,where the motten alloy is poured into sand molds,AlNiCo is hard and brittle,and is not suitable for drilling,tapping or conventional machining operations. |

|

| AlNiCo magnets are very good in temperature properties, its temperature coefficient is very low, so the change of magnetic properties is low under high temperature. The maximum working temperature can be as high as 400 oC for |

| these magnets. So AlNiCo magnets are still widely used in applications such as instruments, meters, which these kind of applications need very stable temperature properties. |

| The coercive force of AlNiCo magnets is very low, so it can be easily effected by reverse magnetic force, impact or touched by iron. This means that they can be easily demagnetized by external influences. For this reason, AlNiCo magnets should not be stored and packed with the same poles opposing each other. |

| In open circuit, the ration of length/diameter (L/D) should be at least 4:1. With shorter length, AlNiCo magnets are unstable in open circuit. |

AlNiCo magnets have good corrosion resistance characteristic. No coating is needed for surfac e protection . |

|

|

|